Introduction

When you look under the hood of your car, you’ll find a complex web of wires connecting every major component — from the engine to the lights and sensors. This intricate network is known as the wiring harness, and it serves as the central nervous system of your vehicle. Without it, modern cars simply wouldn’t function. In this detailed guide, “Top Tips: What Is Wiring Harness In Automobile Explained,” we’ll break down what a wiring harness is, how it works, its key components, and why it’s one of the most vital parts of automotive engineering.

Understanding the Wiring Harness in Automobiles

A wiring harness is a carefully organized bundle of electrical cables, connectors, and terminals that transmits electric power and signals throughout the vehicle. It connects various components such as sensors, actuators, lights, ignition systems, and infotainment units.

Instead of running multiple individual wires all over the car, manufacturers use a harness to simplify the design, reduce space, and enhance reliability. It ensures every electrical part communicates efficiently and receives the necessary power for smooth performance.

Modern vehicles may contain more than 1,500 wires, stretching over several kilometers in length. The wiring harness brings structure and safety to this complexity, ensuring that electrical systems operate harmoniously without interference.

The Role and Function of a Wiring Harness

The main function of a wiring harness is to supply electrical power and transmit signals between various parts of the vehicle. In essence, it’s the vehicle’s circulatory system for electricity.

It powers systems like the fuel pump, starter motor, headlights, sensors, and even the infotainment display. The harness also ensures safety by protecting electrical wires from wear, vibration, and heat, which are common in an automobile’s harsh environment.

Additionally, it helps streamline assembly during manufacturing. By grouping wires together in one harness, engineers can easily install or replace electrical systems, reducing labor time and minimizing installation errors.

Components of a Wiring Harness

A wiring harness isn’t just a random collection of wires. It consists of several critical components working together:

Wires and Cables: These conduct electricity between components. They’re made from materials like copper or aluminum for efficient conductivity.

Connectors: These join different parts of the electrical system, ensuring a secure and stable connection.

Terminals: The metal ends that connect wires to components such as sensors or batteries.

Fuses and Relays: These protect the circuit from overcurrent and allow control of high-power systems through low-power signals.

Protective Sheaths and Tapes: These safeguard the harness from moisture, heat, and physical damage.

Clamps and Grommets: These hold the harness in place and reduce vibration or friction damage.

Each part is carefully engineered to ensure reliability and safety under extreme automotive conditions.

Types of Wiring Harnesses in Automobiles

Depending on the function and area of use, wiring harnesses come in several types:

-

Engine Wiring Harness: Controls engine functions like ignition, fuel injection, and sensors.

-

Chassis Wiring Harness: Powers components on the chassis such as brake systems and suspension sensors.

-

Dashboard Wiring Harness: Connects the instrument panel, infotainment system, and switches.

-

Lighting Wiring Harness: Supplies power to headlights, taillights, and indicators.

-

Battery Wiring Harness: Connects the battery to the main electrical system and alternator.

Each harness is custom-designed for its location and purpose to ensure performance efficiency.

Importance of Wiring Harness in Automotive Design

The wiring harness plays a pivotal role in ensuring smooth operation and driver safety. Its design determines the reliability of the car’s electrical systems. A well-designed harness ensures there are no loose connections, short circuits, or voltage drops that could affect performance.

Moreover, as vehicles evolve toward electrification, the complexity and importance of wiring harnesses have grown significantly. Electric and hybrid vehicles depend heavily on precise wiring for battery management and motor control.

A faulty harness could lead to major failures such as engine malfunction, lighting issues, or even safety system breakdowns — making quality and testing vital during production.

How a Wiring Harness Works in an Automobile

When you turn the ignition key, the wiring harness channels electrical energy from the battery to different components that start the engine. It also ensures that signals from sensors are sent to the car’s control unit (ECU), which processes the data and adjusts performance accordingly.

For instance, if the temperature sensor sends data through the harness to the ECU, it can modify fuel injection or cooling fan speed for optimal engine temperature. This interconnected flow of information and power is what keeps modern vehicles intelligent and efficient.

If you want to learn how this process connects to the heart of your vehicle, read What Is An Automobile Engine — for a deeper understanding of how engines rely on these electrical systems.

Benefits of an Efficient Wiring Harness

An efficient wiring harness provides numerous advantages:

-

Improved Reliability: Reduces loose connections and short circuits.

-

Simplified Assembly: Makes vehicle manufacturing and maintenance easier.

-

Enhanced Safety: Protects against overheating and electrical fires.

-

Cost-Effective: Reduces maintenance and replacement costs.

-

Weight Reduction: Organized wiring helps reduce vehicle weight and improves fuel efficiency.

When a harness is designed efficiently, it ensures that all electrical components perform optimally under every driving condition.

Common Problems in Wiring Harnesses

Like any automotive component, wiring harnesses can suffer from wear and tear. Common issues include:

-

Corrosion: Caused by exposure to moisture and road salts.

-

Loose Connections: Due to vibration and poor assembly.

-

Broken Wires: From bending or overheating.

-

Short Circuits: Occur when insulation fails or wires touch each other.

-

Connector Damage: Results in intermittent or complete power loss to systems.

Regular inspection and maintenance are crucial to prevent these issues from escalating into costly repairs.

Diagnosing and Fixing Wiring Harness Problems

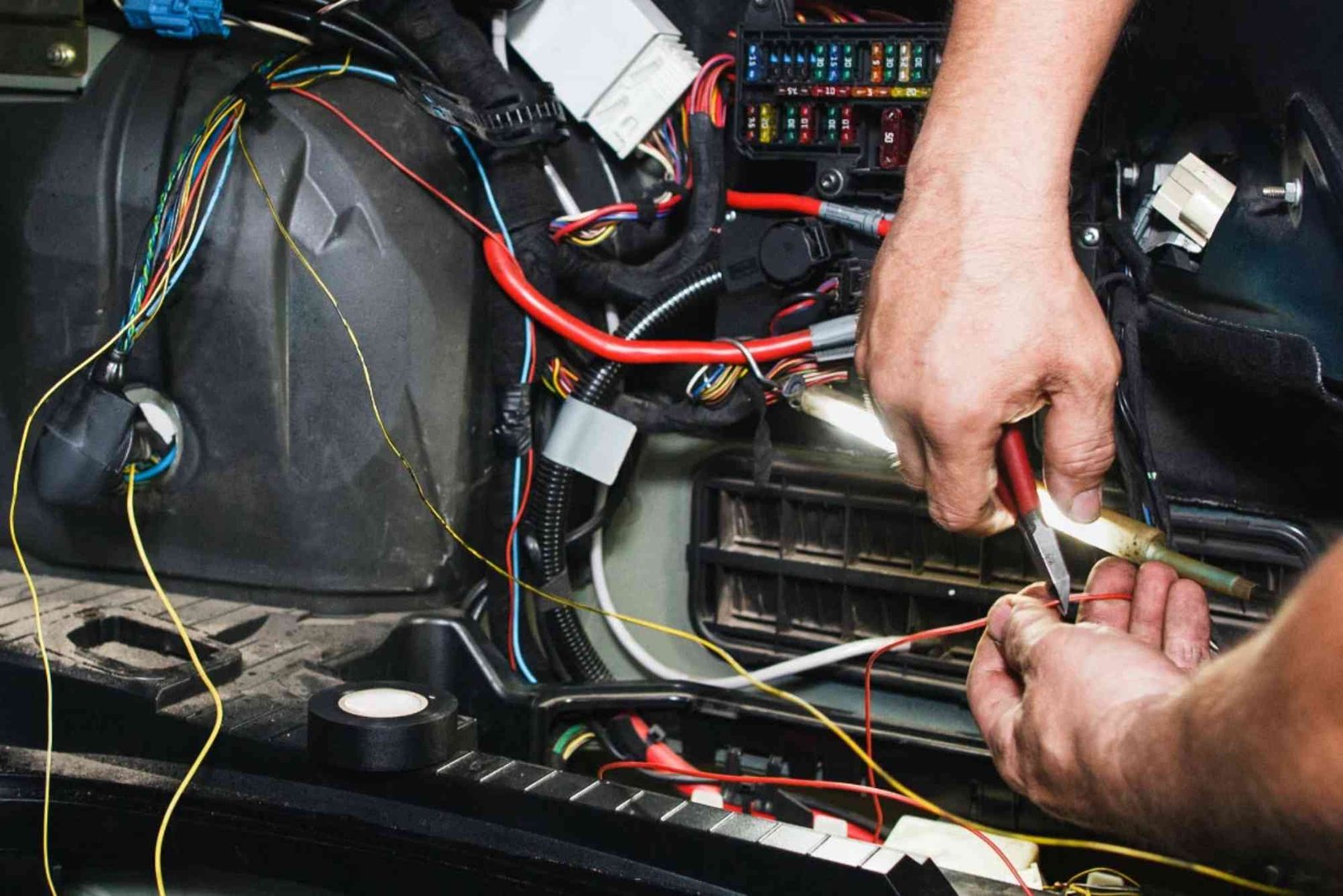

Modern diagnostic tools help mechanics detect wiring issues quickly. Using multimeters and scanning devices, technicians can identify voltage drops, open circuits, or faulty connectors.

In some cases, repairing involves re-soldering broken wires or replacing connectors. However, severe damage may require a complete harness replacement — a complex but necessary process for long-term reliability.

Understanding how electrical systems connect is just as essential as knowing how engines work. To explore more about automotive systems, check Top Tips: What Is An Automobile for a related insight into vehicle fundamentals.

Advances in Automotive Wiring Technology

As vehicles become more advanced, so do their wiring harness systems. Modern harnesses are designed with lightweight materials, improved insulation, and smart diagnostic features.

Lightweight Materials: Using aluminum and composite wiring helps reduce vehicle weight and increase fuel efficiency.

Modular Design: Allows easier replacement and customization of individual harness sections.

Smart Sensors: Integrated sensors can detect temperature or resistance changes in the wiring, preventing failures.

Automated Assembly: Robotic systems ensure precision and consistency in harness production.

These innovations make wiring harnesses more efficient, eco-friendly, and capable of supporting high-tech features like driver assistance systems and electric propulsion.

Wiring Harness and Vehicle Safety

A vehicle’s safety systems — airbags, ABS, traction control, and lane assist — all depend on a reliable wiring network. A single damaged wire could disrupt these lifesaving systems.

Therefore, manufacturers perform extensive testing on wiring harnesses, including vibration, heat, and salt exposure tests, to ensure durability. Quality assurance in harness design directly translates to enhanced passenger safety.

Just like What Is The Necessity Of Lubrication is crucial for smooth engine function, proper wiring ensures your car’s electrical systems operate seamlessly for years.

Future of Wiring Harness in Electric Vehicles

The rise of electric vehicles (EVs) has transformed wiring harness design. EVs require high-voltage harnesses that can handle large amounts of power safely. These advanced harnesses use special shielding to prevent electromagnetic interference and overheating.

In addition, EV manufacturers are exploring flat wiring harnesses and optical fiber systems for faster communication and reduced weight. The next generation of vehicles may rely on fully digital wiring systems with AI-powered diagnostics.

In summary, the wiring harness is the lifeline of every automobile, ensuring power and communication flow smoothly between all parts of the vehicle. Without it, even the most advanced car would be inoperative.

Understanding “Top Tips: What Is Wiring Harness In Automobile Explained” helps you appreciate how essential electrical systems are to your vehicle’s reliability and performance. Whether you’re a car enthusiast or simply curious about how your car works, knowing how wiring harnesses function deepens your automotive knowledge.

If you want to explore more about how vehicles work and their internal systems, visit GloriousTip.com for practical guides and automotive insights.

FAQs

What is a wiring harness used for in an automobile?

A wiring harness connects and powers all electrical components, ensuring efficient signal transmission and reliable performance.

What are the symptoms of a bad wiring harness?

Common symptoms include flickering lights, malfunctioning sensors, and unexpected warning lights on the dashboard.

Can a wiring harness be repaired?

Yes, minor damage can be repaired by soldering or replacing connectors, but extensive damage may require a full replacement.

How much does a wiring harness replacement cost?

The cost depends on the vehicle type and complexity. It can range from $200 for small repairs to $2,000 for full replacements.

Why is the wiring harness important in electric vehicles?

In EVs, it carries high-voltage power safely between the battery, motor, and control units, making it vital for efficient performance.