In modern automobiles, the wiring harness plays a crucial role in ensuring smooth functionality of various electrical components. With the increasing complexity of vehicles, understanding What Is Wiring Harness In Automobile is essential for anyone involved in the automotive industry or vehicle maintenance. This article explores the concept of a wiring harness, its functions, components, and how it integrates into an automobile.

What Is a Wiring Harness?

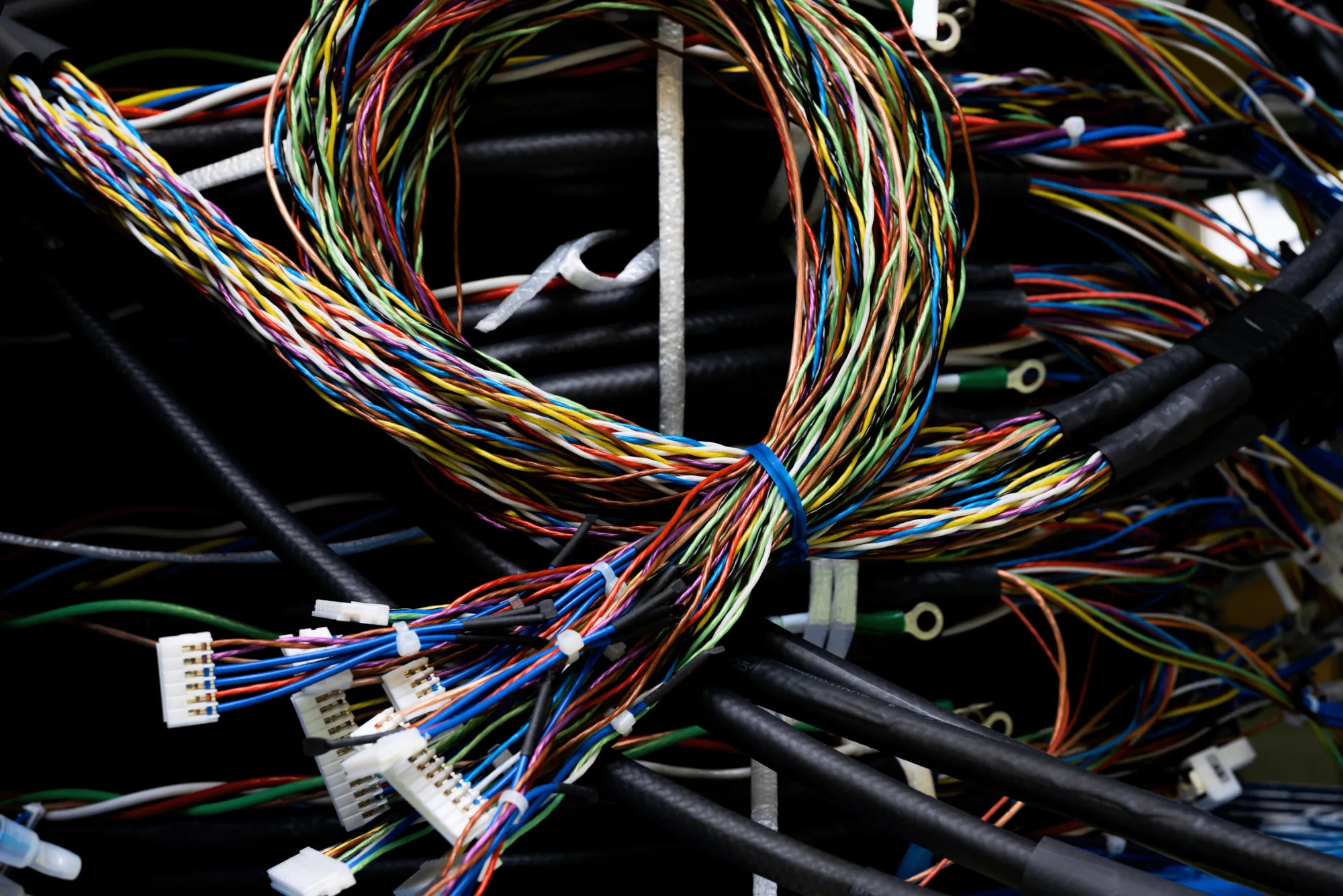

A wiring harness is an organized set of wires, terminals, and connectors that run throughout a vehicle, linking different electrical and electronic components. It acts as the central nervous system for the vehicle, carrying electric signals and power to different parts. The harness simplifies the electrical system of the vehicle by bundling many wires into one assembly, which reduces clutter and makes troubleshooting easier. Without the wiring harness, connecting each component to the battery and control modules would be chaotic and inefficient.

Functions of a Wiring Harness in Automobiles

The primary function of the wiring harness is to distribute electrical power and signals to the components within the vehicle. Modern vehicles rely heavily on electrical systems for lighting, heating, cooling, starting, and many other functions. The wiring harness ensures that each component gets the required power and signals in a structured manner. Additionally, it offers several other critical functions:

- Simplifying the Electrical Layout: Instead of a complex network of individual wires, the wiring harness streamlines the layout by organizing the wires.

- Enhancing Vehicle Safety: A well-designed wiring harness reduces the risk of short circuits and electrical fires, enhancing overall vehicle safety.

- Durability and Protection: The wiring harness is designed to withstand the harsh conditions within an automobile, including heat, vibrations, and exposure to chemicals.

Components of a Wiring Harness

To understand What Is Wiring Harness In Automobile, it’s essential to explore its main components:

| Component | Description |

|---|---|

| Wires | Primary conductors of electrical signals and power |

| Connectors | Attach the wires to various electrical components for secure connections |

| Terminals | Metal components at the ends of wires that fit into connectors |

| Fuses | Protect the wiring harness from electrical surges |

| Relays | Control the flow of electrical power to various systems |

Importance of Proper Wiring Harness Design

A poorly designed or installed wiring harness can lead to a range of problems, including malfunctioning electrical systems and safety risks. For instance, if the harness is too close to high-temperature areas, it may degrade faster and become prone to short circuits. Hence, the design of the wiring harness must be both functional and reliable, ensuring long-term performance without frequent maintenance.

How a Wiring Harness Is Manufactured

The manufacturing of a wiring harness involves several stages. The process starts with designing the harness according to the vehicle’s specific needs. This involves creating a wiring diagram that outlines the layout, connections, and specifications for the wires and connectors. After the design is finalized, the actual production begins:

- Cutting and Stripping the Wires: The wires are cut to the desired length and stripped at the ends to expose the conductive material.

- Crimping Terminals: Terminals are crimped to the wires to allow easy connection to the connectors.

- Assembly: The wires are grouped together and assembled into bundles with connectors attached at the ends. Clips and other securing mechanisms are used to ensure the harness maintains its shape and fits properly within the vehicle.

- Testing: The finished harness undergoes rigorous testing to ensure there are no electrical faults, breaks, or short circuits.

Types of Wiring Harnesses in Automobiles

Wiring harnesses come in different types, depending on the specific application within the vehicle:

| Type | Description |

|---|---|

| Main Wiring Harness | Connects major components like the engine and control modules |

| Engine Wiring Harness | Connects sensors, fuel injectors, and ignition components |

| Chassis Wiring Harness | Powers components located on the chassis, including lights |

| HVAC Wiring Harness | Controls heating, ventilation, and air conditioning components |

| Battery Cable Harness | Transmits electrical power from the battery to the starter |

How Wiring Harness Impacts Vehicle Performance

A well-designed wiring harness directly impacts the vehicle’s performance. For example, the engine wiring harness connects sensors that provide vital data to the engine control unit (ECU). This data helps the ECU optimize fuel consumption, ignition timing, and other parameters, leading to better engine performance. Similarly, the chassis wiring harness plays a vital role in controlling braking systems and ensuring the safety of the vehicle.

Challenges in Wiring Harness Design

While the wiring harness is an essential component of any automobile, designing it presents several challenges:

- Weight: In an era where automakers are looking to reduce the weight of vehicles to improve fuel efficiency, the wiring harness can become a significant factor due to its size and complexity.

- Heat Resistance: The harness must be designed to withstand extreme temperatures, particularly in areas close to the engine.

- Signal Interference: Electrical systems in modern cars can experience signal interference, particularly with the rise of wireless technology in vehicles. The wiring harness needs to be shielded and organized properly to avoid these issues.

- Compatibility: As vehicles become more complex, the wiring harness must be compatible with a wide range of electrical components and systems, such as advanced driver-assistance systems (ADAS) and infotainment systems.

Maintenance of Wiring Harnesses

Maintaining the wiring harness is critical for the longevity of an automobile. Over time, wires can degrade due to heat, moisture, or wear and tear. Regular inspections can help identify any damaged wires or connectors. In cases where the harness is damaged, repairs should be done promptly to avoid electrical failures. Cleaning connectors, ensuring proper insulation, and checking for corrosion are also important aspects of wiring harness maintenance.

Innovations in Wiring Harness Technology

As technology continues to advance, the wiring harness is evolving as well. Automakers are investing in new materials and designs that reduce the weight of the harness while improving its durability and efficiency. For instance, fiber optic cables are now being considered for future wiring harnesses due to their ability to transmit data at high speeds without electrical interference. Additionally, modular wiring harnesses are becoming popular, allowing for easier upgrades and repairs.

The wiring harness is a critical component in modern automobiles, acting as the electrical backbone of the vehicle. Understanding What Is Wiring Harness In Automobile is essential for anyone involved in automotive design, repair, or maintenance. From providing power to ensuring smooth communication between electronic components, the wiring harness plays a pivotal role in the functionality and safety of vehicles. As automotive technology continues to advance, the wiring harness will evolve, becoming even more integral to the next generation of vehicles.