Lubrication systems in automobiles play a vital role in ensuring the smooth and efficient operation of an engine and its related components. The continuous friction and movement inside the engine produce heat, which, without proper lubrication, would lead to excessive wear, reduced performance, and even mechanical failure.

In modern vehicles, the necessity of an effective lubrication system cannot be overstated. This article will delve into the importance, functionality, and types of lubrication systems in automobiles. We will also explore common issues related to lubrication systems and the significance of regular maintenance. Additionally, John Auto Spare Parts provides high-quality parts and lubricants to help keep your vehicle running smoothly.

The Basics of Lubrication Systems in Automobiles

A lubrication system ensures that all moving parts in an engine receive sufficient lubrication to minimize friction, control heat, and prevent wear. Without lubrication, metal parts would grind against each other, producing heat and causing wear. In severe cases, this can lead to engine failure. Lubricants, usually oil or grease, form a thin film between parts, allowing them to slide over each other with minimal resistance.

Why is Lubrication Important in Automobiles?

In automobiles, engines consist of various moving parts, each with the potential to generate heat due to friction. If left unchecked, this friction would cause excessive wear and tear on the components, reducing the vehicle’s efficiency and leading to frequent breakdowns. The lubrication system reduces this friction by forming a protective layer over the metal surfaces. Moreover, the system helps in cooling the engine and prevents the formation of harmful deposits inside the engine components. Below are some specific reasons why a lubrication system is necessary in an automobile.

Friction and Wear Reduction

The most fundamental function of a lubrication system is to reduce friction between the moving parts in an engine. By minimizing direct metal-to-metal contact, it ensures that components such as pistons, bearings, and crankshafts can function without degrading due to excessive heat and wear.

Heat Dissipation

As the engine runs, it generates a significant amount of heat. The lubrication system helps carry this heat away from the engine’s moving parts, dissipating it into the oil pan or an external oil cooler. By keeping the engine at a stable temperature, the system prevents overheating and reduces the risk of engine damage.

Cleaning and Debris Removal

As oil circulates through the engine, it picks up dirt, metal particles, and other contaminants that could cause damage if left unchecked. The oil filter then removes these impurities, allowing clean oil to continue lubricating the engine. This cleaning action prevents the buildup of sludge and varnish, which can clog engine passages and reduce performance.

Sealing Effect

Another critical function of the lubrication system is sealing the gaps between engine parts. This is particularly important in the combustion chamber, where a proper seal is required for efficient engine operation. Lubrication oil acts as a sealant, preventing combustion gases from leaking out and helping to maintain optimal pressure for power generation.

Corrosion Prevention

Lubricating oil also prevents corrosion by forming a protective layer over metal surfaces. This layer shields the metal from water, oxygen, and other corrosive elements that could lead to rust and other forms of deterioration.

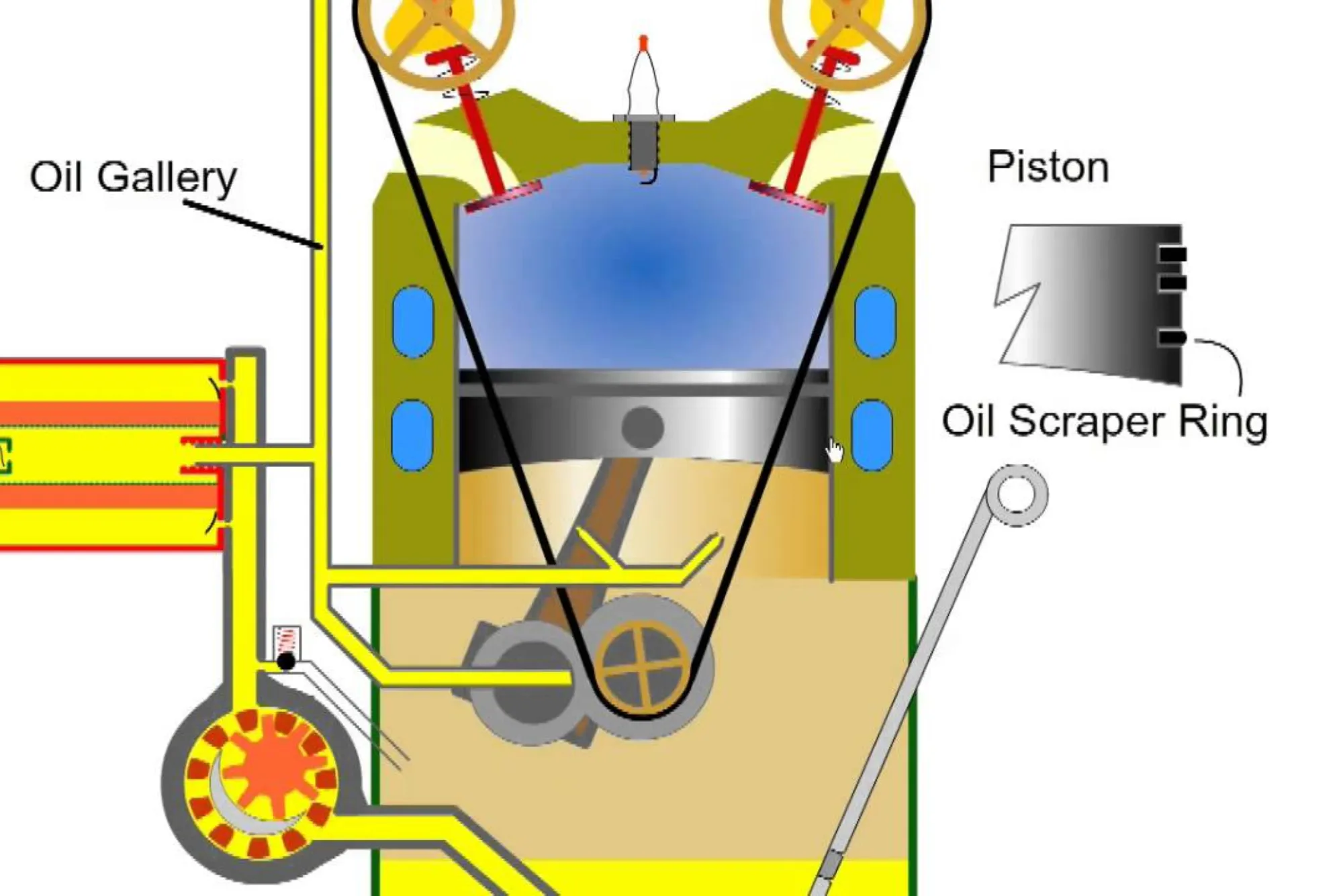

Components of a Lubrication System

To understand the necessity of the lubrication system, it is essential to grasp its various components and how they work together to keep the engine running efficiently. These components include:

Oil Pan

The oil pan, also known as the oil sump, is located at the bottom of the engine. It serves as a reservoir where the oil is stored when the engine is not in operation. When the engine starts, oil is drawn from the oil pan by the oil pump and circulated throughout the engine.

Oil Pump

The oil pump is responsible for drawing oil from the oil pan and delivering it under pressure to the various engine components. The pump ensures that oil reaches every critical area, including the crankshaft, camshaft, and piston rings.

Oil Filter

The oil filter is a crucial part of the lubrication system. Its primary function is to remove contaminants, such as dirt and metal particles, from the oil before it circulates through the engine. This ensures that only clean oil reaches the moving parts, preventing damage and prolonging the life of the engine.

Oil Cooler

In high-performance engines, an oil cooler is often used to reduce the temperature of the oil before it recirculates through the engine. This helps maintain optimal oil viscosity and ensures that the lubrication system can operate effectively even under extreme conditions.

Pressure Relief Valve

The pressure relief valve ensures that the oil pressure within the engine remains within safe limits. If the pressure exceeds the set threshold, the valve opens to release excess oil, preventing damage to engine seals and other components.

Types of Lubrication Systems

Various types of lubrication systems are used in automobiles, depending on the design and application of the vehicle. The most common types are:

Wet Sump Lubrication System

The wet sump system is the most widely used lubrication system in automobiles. In this system, oil is stored in the oil pan (or sump) and is pumped by the oil pump to the engine components. After circulating through the engine, the oil returns to the oil pan for recirculation.

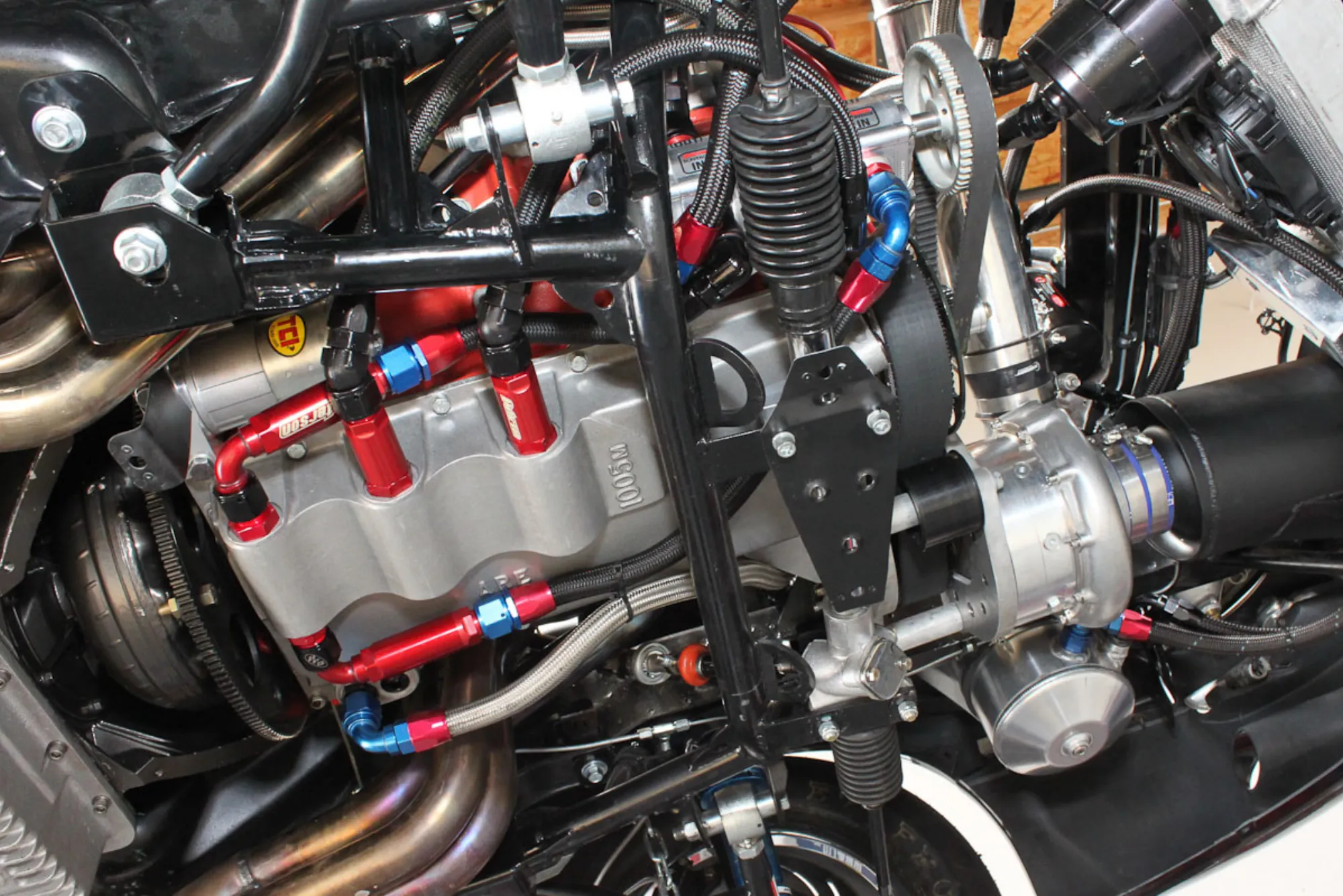

Dry Sump Lubrication System

In a dry sump system, oil is stored in an external tank rather than the oil pan. This system is typically used in high-performance vehicles and racing cars, as it allows for better control of oil levels and reduces the risk of oil starvation during high-speed maneuvers.

Splash Lubrication System

In this system, oil is splashed onto the moving parts by the action of the components themselves. Splash lubrication is commonly used in small engines and older vehicles, where the simplicity of the system outweighs the need for precise oil control.

Forced Lubrication System

In a forced lubrication system, oil is pumped under pressure to all critical engine components. This system ensures that every part receives sufficient lubrication, even under extreme operating conditions. It is commonly used in heavy-duty vehicles and industrial machinery.

Common Issues in Lubrication Systems

Although lubrication systems are designed to be reliable, several issues can arise if they are not properly maintained. Below are some common problems and their potential consequences:

| Issue | Cause | Effect | Solution |

|---|---|---|---|

| Low Oil Levels | Oil leaks or insufficient oil | Increased friction and engine overheating | Regularly check and top up oil |

| Oil Contamination | Dirt, debris, or metal particles | Clogged passages and reduced lubrication | Replace oil and filter regularly |

| Oil Leaks | Worn seals, gaskets, or oil lines | Reduced oil levels and performance | Repair or replace damaged parts |

| Sludge Buildup | Oil breakdown due to heat | Clogged engine parts and reduced performance | Perform routine oil changes |

| Oil Pump Failure | Worn gears or clogged passages | Inadequate lubrication and potential engine damage | Replace faulty oil pump |

Importance of Regular Maintenance

To ensure that the lubrication system functions properly, regular maintenance is essential. This includes routine oil changes, oil filter replacements, and inspections of the oil pump and other components. By following the manufacturer’s recommended maintenance schedule, vehicle owners can prevent costly repairs and extend the lifespan of their engine.

John Auto Spare Parts

When it comes to maintaining your vehicle’s lubrication system, John Auto Spare Parts offers a wide range of high-quality parts and lubricants. Whether you need oil filters, oil pumps, or lubricating oils, their products are designed to meet the highest standards of performance and durability. Ensuring that your vehicle receives the best possible care will not only enhance its performance but also prolong its lifespan.

The lubrication system is a critical component of any automobile, providing essential protection for the engine and its moving parts. By reducing friction, dissipating heat, cleaning contaminants, and sealing gaps, the lubrication system ensures that the engine operates efficiently and reliably. Regular maintenance, including oil changes and inspections, is crucial for keeping the lubrication system in top condition. Vehicle owners who prioritize proper lubrication can expect improved performance, reduced wear, and longer engine life. With high-quality products from John Auto Spare Parts, maintaining your lubrication system has never been easier.